A new generation of p-type polymer is coming!

#newatbrilliantmattersA new generation of p-type polymers is coming!

Like everything, science has its trends. In the case of organic photovoltaics (OPV), success was measured almost entirely by breaking the current record of light-to-electricity conversion efficiency, known among the scientific community as the power conversion efficiency (PCE). Performances have now reached over 17%[1-2], which is mind-blowing when we think they are made from organic materials! As OPV is currently the greenest solar cell technology, this is great to see such tremendous progress unfold.

In this race for performance, cost and scalability considerations took a back seat and because of that, we now realize that most trending organic semiconductors are not as perfect as advertised. From a chemist’s point of view, the most used p-type conjugated polymers have overly complex chemical structures and require a lot of chemical transformations to obtain. The PBDB-T-2F and PTB7-Th are examples of conjugated polymers that, while being high-performance materials, incorporate fluorine atoms in very inconvenient chemical positions that make them pretty difficult to produce efficiently.

As more and more companies are now willing to invest in this technology (which is awesome!), all these little details become growing pains and roadblocks for the deployment of OPV. How can we make this technology viable if the materials cause unnecessary device manufacture challenges or make the solar panels too expensive? How can we meet the expectations that organic solar cells are an affordable source of renewable energy?

First, let’s take a step back and determine what would actually be an ideal organic semiconductor for OPV. To have a successful combination, we need:

- Performance: no compromise there!

- Processability: to be printable commercially

- Stability: for high device lifetime

- Cost: crucial to reduce the cost per watt to competitive levels

Fortunately, an increasing number of researchers have taken the entirety of this challenge seriously. As a result, we have seen an increase of examples of organic semiconductors better suited for scale-up. For example, PBDB-T and PBDB-T-2Cl, analogs to PBDB-T-2F, are both obtained using simpler chemical preparation methods and show improved scalability.

But what if instead of incremental improvements on existing high-performance materials, we started from scratch? Starting from simple to make chemical structures, and then work on increasing the performance, stability and processability? It turns out researchers from the Chinese Academy of Science successfully used this concept and came up with a very promising solution. In 2018, they published results demonstrating a new polymer semiconductor, PTQ10, that is very easy to make and that could still reach efficiencies of over 12%. [3]

It only required the researchers a combined 2 chemical transformations steps from a commercial precursor to synthesize it, which is a lot less than the usual 8-15 steps of other materials (see Riccardo et al for an excellent overview of the subject)[4]. This is great as it saves a lot of time, and everyone knows that time is money!

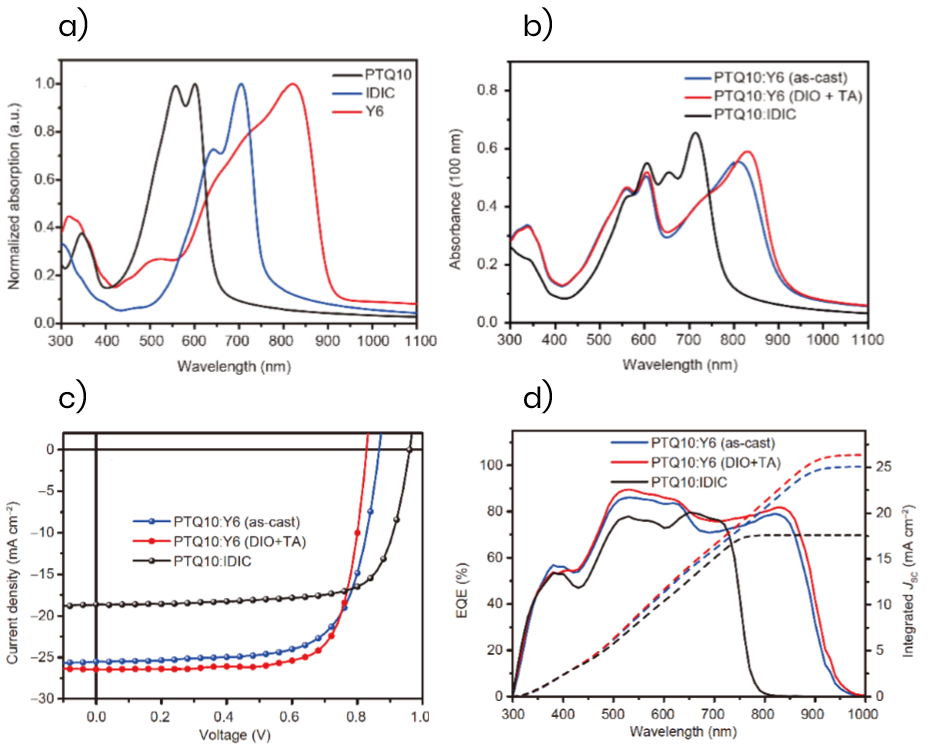

Now it turned out that this work was only the beginning and PTQ10 has quietly been integrated into increasingly improved devices, showing its versatility and potential for high performance. Part of its success comes from advantageous optoelectronic properties. Compared to previous trending materials, PTQ10 has a higher bandgap, which conventional wisdom would dictate shouldn’t be beneficial. Indeed, this leads to weak overall photon absorption and spectrum overlap with popular n-type fullerene derivatives in the 300-500 nm region. However, things have become much less straightforward with the new n-type non-fullerene organic semiconductors called NFAs. These materials often have a much stronger absorption at medium to low gap, but they also have a very weak absorption below 500-600 nm. This is exactly where the high bandgap PTQ10 absorbs photons! A perfect match, that leads to increased photocurrent. [5] This brought impressive performances of 16.5% PCE when combined with the popular Y6 NFA, a value that ranks among the very best. [6]

Figure 1: a) Thin-film normalized absorption spectra of PTQ10, Y6 and IDIC b) Absorption spectra of PTQ10:Y6 (1:2, w/w) and PTQ10:IDIC (1:1, w/w) c) J-V curves of OPVs made from PTQ10:Y6 (1:2, w/w) and PTQ10:IDIC (1:1, w/w) d) EQE and integrated Jsc of the devices based on PTQ10:Y6 and PTQ10:IDIC (image from Sci. China Chem. 2020, 63, 265) [6]

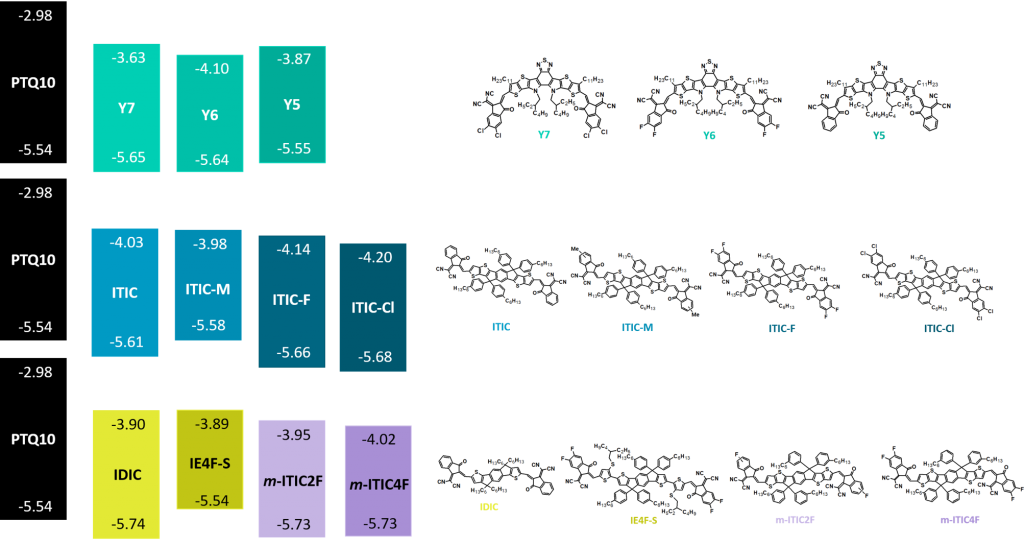

PTQ10 is also a good match with many NFAs due to its electronic energy levels. As seen in the illustration below, its low-lying HOMO of -5.54 eV aligns well with those of several high performing acceptors. Combined with a high lying LUMO level, this really is key to improve the Voc of the cells and limits the energy losses. [7,8]

Figure 2: Representation of the HOMO LUMO levels of PTQ10 compared with different Non-Fullerene organic semiconductors

Performances and scalability of PTQ10 are definitely selling points, but what about the processability? PTQ10 is a polymer that is soluble and printable using solvents compatible with industrial processes (i.e. xylene, trimethylbenzene, etc.). This is important as the most used (and often best) solvents for making OPV devices in the lab are chlorinated, which is a no-go due to safety hazards associated with their toxicity. [9]

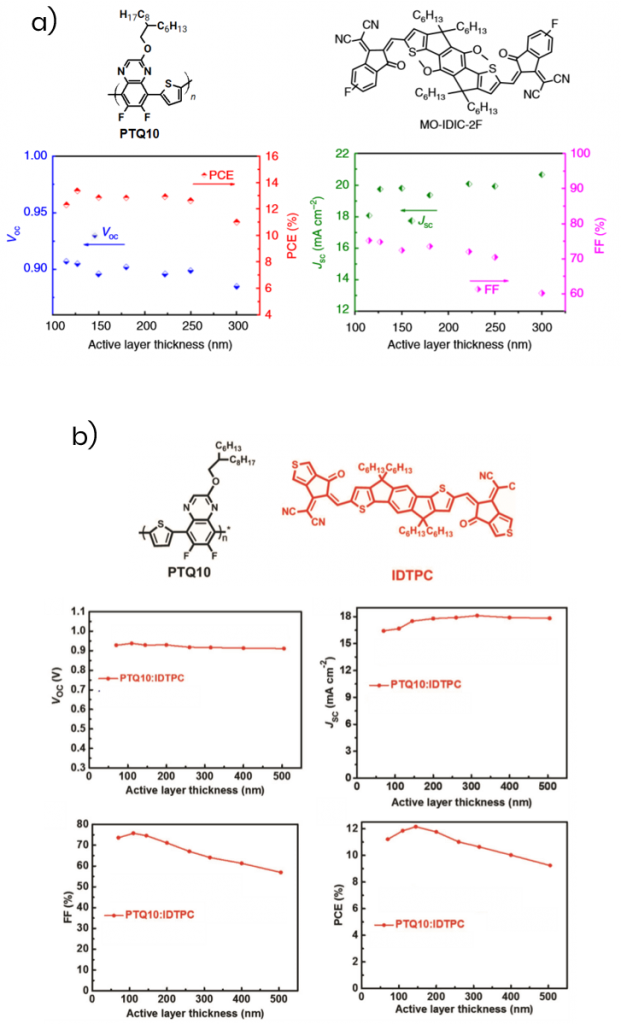

Furthermore, blends of PTQ10 with NFAs have demonstrated their good performances in varying thicknesses, making it a robust material to work with. Most of the p-type polymers tend to have a rapid decrease of performances with small thickness variations of only tens of nanometers. PTQ10, on the other hand, is quite robust in this regard. Examples of blends with high PCEs are reported by researchers for thicknesses ranging from 70 to 500nm! Some examples are depicted below:

Figure 3: a) Voc, PCE, Jsc and FF of the active layer with a range of thickness from 115 to 300 nm for the PSCs based on PTQ10: MO-IDIC-2F (1:1, w/w) with thermal annealing at 110 °C for 5 min by Li et al. Nature Commun. 2019, 10, 519. [10] b) Voc, Jsc, FF and PCE of the active layer with a range of thickness from 70 to 500 nm composed of PSCs based on PTQ10:IDTPC (1:1, w/w) by Luo, et al. Adv. Energy Mater. 2018, 8, 1800856. [11]

To summarize what we know of PTQ10, here is a list of some of its standout features:

- Performances > 16%

- Compatible with many non-fullerene acceptors

- Printable in non-chlorinated solvents

- Simple and scalable synthesis (2 steps)

- Performs well at various layer thicknesses

With this much upside, this polymer is here to stay. We would go as far as saying it might be the new black, and it might only be the first of its generation. If you are interested in this material, it is available here! Or If you want to request a free sample, just click on the sample request at the top of the banner or email us at info@brilliantmatters.com

To be informed of promotions, breakthroughs or new interesting posts like this one, please subscribe to our newsletters and follow us on our social medias

References for this post

1. Liu, Q.; Jiang, Y.; Jin, K.; Qin, J.; Xu, J.; Li, W.; Xiong, J.; Liu, J.; Xiao, Z.; Sun, K.; Yang, S.; Zhang, X.; Ding, L. ‘‘18% Efficiency organic solar cells’’ Sci. Bull. 2020, 10.1016/j.scib.2020.01.001

2. Lin, Y.; Adilbekova, B.; Firdaus, Y.; Yengel, E.; Faber, H.; Sajjad, M.; Zheng, X.; Yarali, E.; Seitkhan, A.; Bakr, O. M.; El-Labban, A.; Schwingenschlögl, U.; Tung, V.; McCulloch, I.; Laquai, F.; Anthopoulos, T. D. ‘‘17% Efficient Organic Solar Cells Based on Liquid Exfoliated WS2 as a Replacement for PEDOT:PSS’’ Adv.Mater. 2019, 31, 1902965

3. Sun, C.; Pan, F.; Bin, H.; Zhang, J.; Xue, L.; Qiu, B.; Wei, Z.; Zhang, Z.-G.; Li, Y. ‘‘A low cost and high-performance polymer donor material for polymer solar cells.’’ Nature Commun. 2018, 9, 743.

4. Po, R.; Bianchi, G.; Carbonera, C.; Pellegrino, A., “All That Glisters Is Not Gold: An Analysis of the Synthetic Complexity of Efficient Polymer Donors for Polymer Solar Cells.’’ Macromolecules, 2005, 48, 453.

5. Li, X.; Yao, J.; Angunawela, I.; Sun, C.; Xue, L.; Liebman-Pelaez, A.; Zhu, C.; Yang, C.; Zhang, Z.-G.; Ade, H.; Li, Y. ‘‘Improvement of Photovoltaic Performance of Polymer Solar Cells by Rational Molecular Optimization of Organic Molecule Acceptors.’’ Adv. Energy Mater. 2018, 8, 1800815

6. Wu, Y.; Zheng, Y.; Yang, H.; Sun, C.; Dong, Y.; Cui, C.; Yan, H.; Li, Y. ‘‘Rationally pairing photoactive materials for high-performance polymer solar cells with efficiency of 16.53%’’. Sci. China Chem. 2020, 63, 265.

7. Zou, Y.; Dong, Y.; Sun, C.; Wu, Y.; Yang, H.; Cui, C.; Li, Y. ‘‘High-Performance Polymer Solar Cells with Minimal Energy Loss Enabled by a Main-Chain-Twisted Nonfullerene Acceptor’’ Chem. Mater. 2019, 31, 4222.

8. Li, S.; Zhan, L.; Sun, C.; Zhu, H.; Zhou, G.; Yang, W.; Shi, M.; Li, C.-Z.; Hou, J.; Li, Y.; Chen, H. ‘‘Highly Efficient Fullerene-Free Organic Solar Cells Operate at Near Zero Highest Occupied Molecular Orbital Offsets’’ J. Am. Chem. Soc. 2019, 141, 3073.

9. Qin, G.; Zhang, L.; Yuan, D.; Jiang, H.; Tang, W.; Chen, M.; Wu, W.; Cao, Y.; Chen, J. ‘‘Simultaneous improvement of three parameters using a binary processing solvent system approach in as-cast non-fullerene solar cells’’ J. Mater. Chem. A, 2019, 7, 25978.

10. Li, X.; Pan, F.; Sun, C.; Zhang, M.; Wang, Z.; Du, J.; Wang, J.; Xiao, M.; Xue, L.; Zhang, Z.-G.; Zhang, C.; Liu, F.; Li, Y. ‘‘Simplified synthetic routes for low cost and high photovoltaic performance n-type organic semiconductor acceptors’’ Nature Commun. 2019, 10, 519.

11. Luo, Z.; Sun, C.; Chen, S.; Zhang, Z.-G.; Wu, K.; Oiu, B.; Yang, C.; Li, Y.; Yang, C. ‘‘Side-Chain Impact on Molecular Orientation of Organic Semiconductor Acceptors: High Performance Nonfullerene Polymer Solar Cells with Thick Active Layer over 400 nm.’’ Adv. Energy Mater. 2018, 8, 1800856.