No Glovebox Required – OPVs Made and Tested in Air!

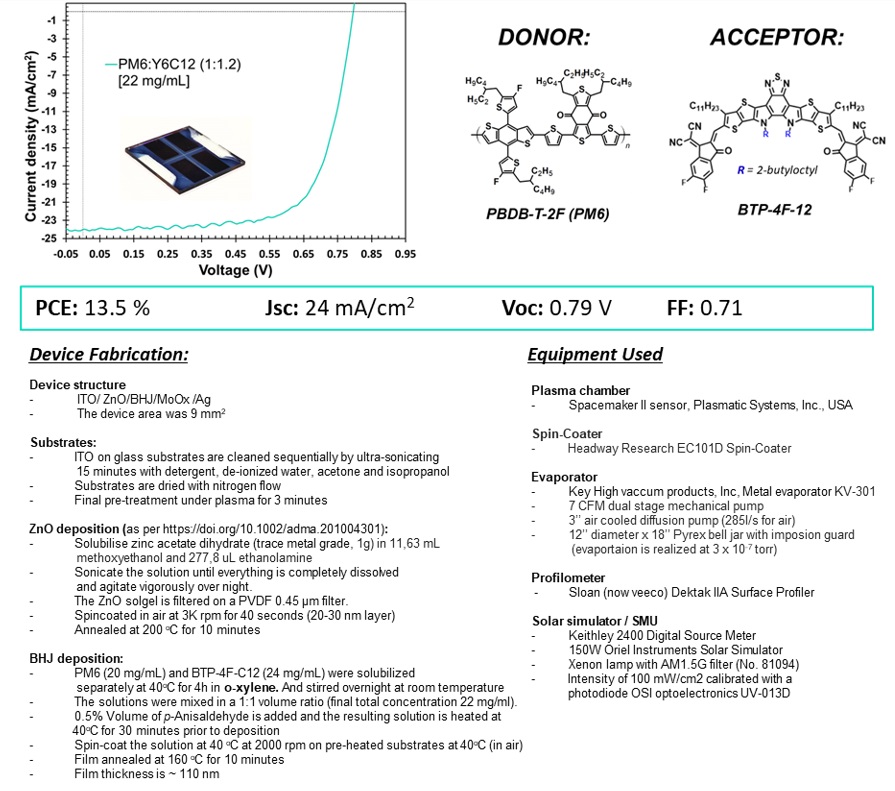

#newatbrilliantmattersThe progress of organic photovoltaics has been truly remarkable in the last few years, with record performances being reported regularly by hard-working researchers all over the world. Today we’re sharing a nice result we got in the lab recently using the donor : acceptor combination of PM6 : BTP-4F-12. This blend is known to give >16% PCE in typical lab cells.1 And here at Brilliant Matters, we obtained a 13.5% PCE!

Now, we know what you are thinking, but trust us, this is a special result (and not just in our heart). For this one, we set the bar higher by trying to more closely mimic what is used at commercial scale. Nonetheless, undeterred, our brave device scientist set out to make it happen. She used our own batches PM6 and BTP-4F-12 and obtained a 13.5% PCE from an “all air-processed and tested” solar cell using non-halogenated solvents. Indeed, the active layer was deposited in air from an o-xylene solution and we also used the (usually) more stable and scalable inverted device architecture.2 Who said you need a glovebox? We don’t.

Check out our J-V curve and device recipe below, feel free to try it at home (or, you know, in the lab!).

Now that we know this system works quite well outside the glovebox, the next step is to move towards larger area and fully printed devices, since rigid substrates and evaporated electrodes are also not compatible with high-throughput roll-to-roll processes! Stability is another area that needs investigation, but we are hopeful we’ll get good results. After all, non-fullerene acceptors (NFAs) are often more photochemically and thermally stable versus their fullerene counterparts.3

With this starting recipe, we hope to help kick-start more major advances in high performance OPV device made using scalable conditions.

(You might have guessed it, but we don’t even have a glove box. There, we’ve said it!)

Do you have any success stories to share using “all in air” fabrication techniques? We would love to hear from you! Do you think you can beat our result with PM6:BTP-4F-12? Head over to our sample request page to get a free sample of these materials and try it yourself and share the result!

You want more information or have questions about the products? please reach us at info@brilliantmatters.com

Working together towards a Brilliant future!

Useful References.

(1) Hong, L.; Yao, H.; Wu, Z.; Cui, Y.; Zhang, T.; Xu, Y.; Yu, R.; Liao, Q.; Gao, B.; Xian, K.; Woo, H. Y.; Ge, Z.; Hou, J. Eco-Compatible Solvent-Processed Organic Photovoltaic Cells with Over 16% Efficiency. Adv. Mater. 2019, 31 (39), 1903441. https://doi.org/10.1002/adma.201903441.

(2) Wang, K.; Liu, C.; Meng, T.; Yi, C.; Gong, X. Inverted Organic Photovoltaic Cells. Chem. Soc. Rev. 2016, 45 (10), 2937–2975. https://doi.org/10.1039/C5CS00831J.

(3) Yan, C.; Barlow, S.; Wang, Z.; Yan, H.; Jen, A. K.-Y.; Marder, S. R.; Zhan, X. Non-Fullerene Acceptors for Organic Solar Cells. Nat. Rev. Mater. 2018, 3 (3), 18003. https://doi.org/10.1038/natrevmats.2018.3.

(4) Brabec, C. J.; Distler, A.; Du, X.; Egelhaaf, H.-J.; Hauch, J.; Heumueller, T.; Li, N. Material Strategies to Accelerate OPV Technology Toward a GW Technology. Adv. Energy Mater. 2020, 10 (43), 2001864. https://doi.org/10.1002/aenm.202001864.

(5) Riede, M.; Spoltore, D.; Leo, K. Organic Solar Cells—The Path to Commercial Success. Adv. Energy Mater. 2020, https://doi.org/10.1002/aenm.202002653.