Making light of Indoor OPV: new record efficiency

#NewproductHave you ever thought about how it would be convenient if your small electronic devices were self-powered? What if your TV remote just charged itself standing in your living room? No longer will you change batteries ever again! And what if you could replenish your cellphone battery while walking in the grocery store? Enhancing its battery autonomy with no effort at all! I’ll let you in on a little secret; this technology is coming and will use light as its power source!

Well, you might think that calculators have been able to do that already since the 80’s. And you’re right, they have a small integrated solar cell! But why aren’t we seeing more of these? Quite simply, these photovoltaic cells are not efficient enough under low-light intensity, like indoor lighting. The main problem is most of these low-cost small solar cells are made from amorphous silicon. When soaked in bright sunlight, they work well and can convert up to 13,4% of photon energy into electricity. But, when exposed to indoor illumination, which is 100 to 1000 times less intense, they only offer ≈ 8% of power conversion efficiencies. [1-2]

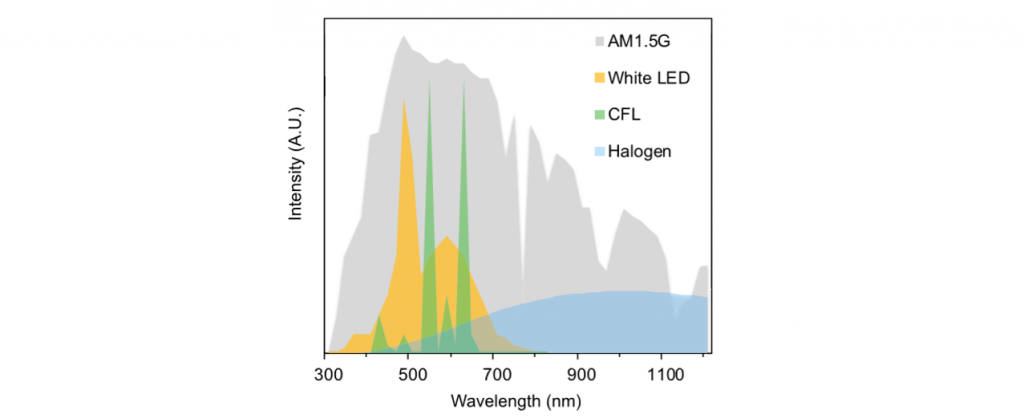

The reason for these lower efficiencies might not seem obvious at a glance, but there is a very rational explanation: Silicon is not adapted for this application! Silicon has a broad absorption spectrum extending to the lower energy near-infrared region. This means two things: 1) It can absorb more light and generate more current (higher amperage) but 2) as a trade-off, the current it generates has lower energy (lower voltage). Silicon is optimal to generate high power from a light source that also has a broad spectrum, like the sun. but modern artificial light sources (i.e. fluorescent, LED, etc.) have a narrow emission typically concentrated in the higher energy visible region (400 to 700 nm). This means silicon leaves a lot of money (power) on the table!

Figure 1: UV-visible-NIR spectrum of typical sources of light (white LED, Fluorescent (CFL) and halogen as well as the simulated solar spectra AM 1.5G) (image from Mathews et al. (linked below))

That’s where organic photovoltaics (OPV for short) steps in! How can OPV improve the performances of solar cells used indoor? Because organic semiconductors can be easily modified to tune their photon absorption spectrum! Power output can thus be maximized for specific situations. Also, those materials have many other benefits. They can be printed on flexible plastic films using high-throughput printing techniques. As the technology matures, you can expect unbeatable prices. And OPV is truly green too, being recyclable and requiring very minimal energy input to produce. This technology also has the highest energy output per weight of any solar cell, meaning it can be integrated more easily into small electronic devices!

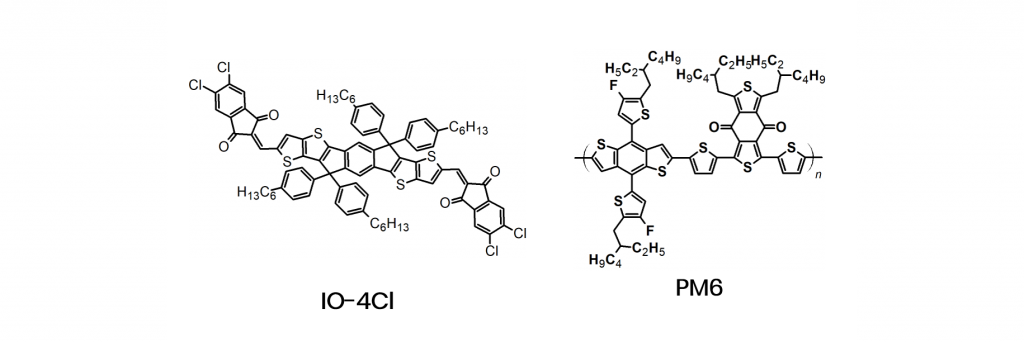

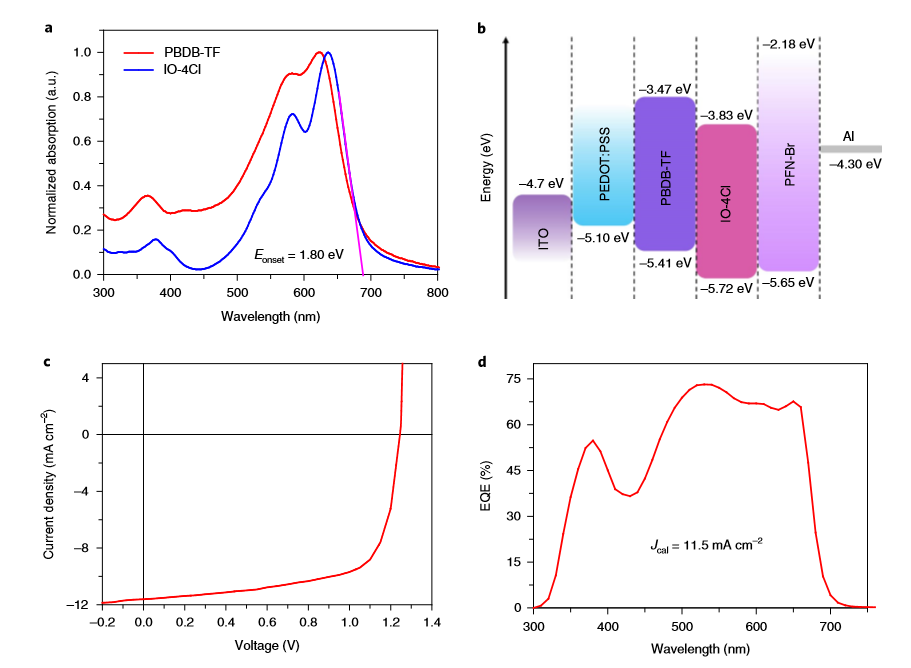

Just off the press is a new study by Hou et al. that clearly demonstrates OPV is a leading technology for indoor light harvesting. Not just in terms of form factor and costs, but also in terms of performances! Using a new high bandgap organic semiconductor (IO-4Cl), the researchers pushed energy conversion to new heights at 26.1% under an illumination of 1000 lux (equivalent to a grocery store lightning). This is more than three times better than amorphous silicon!

The devices also showed no degradation over 1000h of exposure to the LED light. This preliminary test proved that this photovoltaic cell can be even more stable than devices made from other types of semiconductors. In comparison, a device made with amorphous silicon will lose about 8.2% of its efficiency over less than 3 hours under a fluorescent lamp. [3]

Another impressive accomplishment is a high power conversion efficiency of over 23% is maintained when the device is made using blade-coating over a 4 cm2 active area. This lab-scale deposition technique mimics large printers and helps the researcher demonstrate the scalability of the process they developed to make their solar cells.

Here’s the link of the article of Hou et al. : https://www.nature.com/articles/s41560-019-0448-5

Figure 2: Structure of the organic semiconductors IO-4Cl and PM6 (PBDB-TF) used in the publication by Hou et al.

Figure 3: a) UV-visible spectra of PM6 (PBDB-TF) and IO-4Cl in film, b) HOMO/LUMO levels of PM6 and IO-4Cl as well as the configuration of the IOPV c) J-V curve of PM6: IO-4Cl under the illumination of AM 1.5G d) EQE of the PM6: IO-4Cl solar cell (image from the article of Hou et al. linked lower)

At the end of the day, this publication demonstrated that indoor OPV is breaking some major milestones. Its efficiency is now among the highest of all competing technologies in this market. There is also a great potential for large-scale production at an affordable price. All that while retaining the flexibility and eco-friendliness that makes OPV so attractive.

If you want more information on indoor OPV and the opening market of these devices, we recommend reading this article: Mathews et al., Technology and Market Perspective for Indoor Photovoltaic Cells, Joule (2019), https://www.sciencedirect.com/science/article/abs/pii/S2542435119301667

By the way…

PM6 and IO-4Cl material are currently available at Brilliant Matters in our product tab

You want to test our material in your system; request a sample! You want more information or have question about the products? In every case, please reach us at info@brilliantmatters.com

Working together towards a Brilliant future!

[1] Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; Yamamoto, K. Nat. Energy, 2017, 2, 17032 https://www.nature.com/articles/nenergy201732?proof=true

[2] Li, Y.; Grabham, N. J.; Beeby, S. P.; Tudor, M. J., Sol. Energy, 2015, 111, 21 https://www.sciencedirect.com/science/article/abs/pii/S0038092X14005118

[3] Kao, M.-H.; Shen, C.-H.; Yu, P.-C.; Huang, W.-H.; Chueh, Y.-L.; Shiieh, J.-M. Scientific Reports, 2017, 7, 12706 https://www.nature.com/articles/s41598-017-10661-y.pdf